| NO. | Unit | Description |

| 1 | Deliver Unit (LODING C/V) | transfer eggs into cleaning deparment by egg belt on cage. Pulluted and broken eggs will be picked out manually. |

| 2 | Grading Unit (Grader) 0.75kw*3Ø*1SET | grading eggs by size (LLL,LL,L,M,S) grading weight error within ±0.3g. control by CPU. after sorting and grading eggs be separated in 10,12,15, 18,30 pieces for next processing. |

| 3 | Mounting Unit (PACKING STATION) 200W*1Ø*5SET | pack the clean and dry eggs each 10,15,20 in a egg tray. Hourly processing capacity is 30,000 eggs. ( based on 10 eggs per tray) Usually divided into 5 levels, also can be 4 or 3 levels according tofarm productions. |

| 4 | Cleaning Unit 0.4KW*3Ø*2SET | the key of cleaning process is the water for cleaning. (Washer) water in this processing line is for washing and rinsing. average temperature 45~50ºC. temperature of water for washing maintains higher than eggs, preventing wash water from penetrating into eggs. cleaning room and cleaning brush shall keep clean & sanitary |

| 5 | Drying Unit 200W*1Ø*4SET 0.4KW*3Ø*1SET 3.7kw*3Ø*2set | drying after washing to prevent the proliferation of bacteria and germs. |

| 6 | Checking Unit (CANDLING) 100W*1Ø*1SET | three-wavelength fluorescent lamps and halogen lamps are used to detect cleaned eggs, find the broken and unusual eggs. |

| 7 | Ultraviolet Sterilization Unit 15W*1Ø*5SET | irradiation of eggs with ultraviolet light to prevent secondary pollution and keep it clean. By rotating the egg, it is ensured that the whole egg is irradiated, and bacterial growth is minimized. |

| 8 | Defective Discharge Unit 40W*1Ø*1SET | Discharge abnormally shaped eggs, bloody eggs, shelled eggs, and eggs that are too light, etc. |

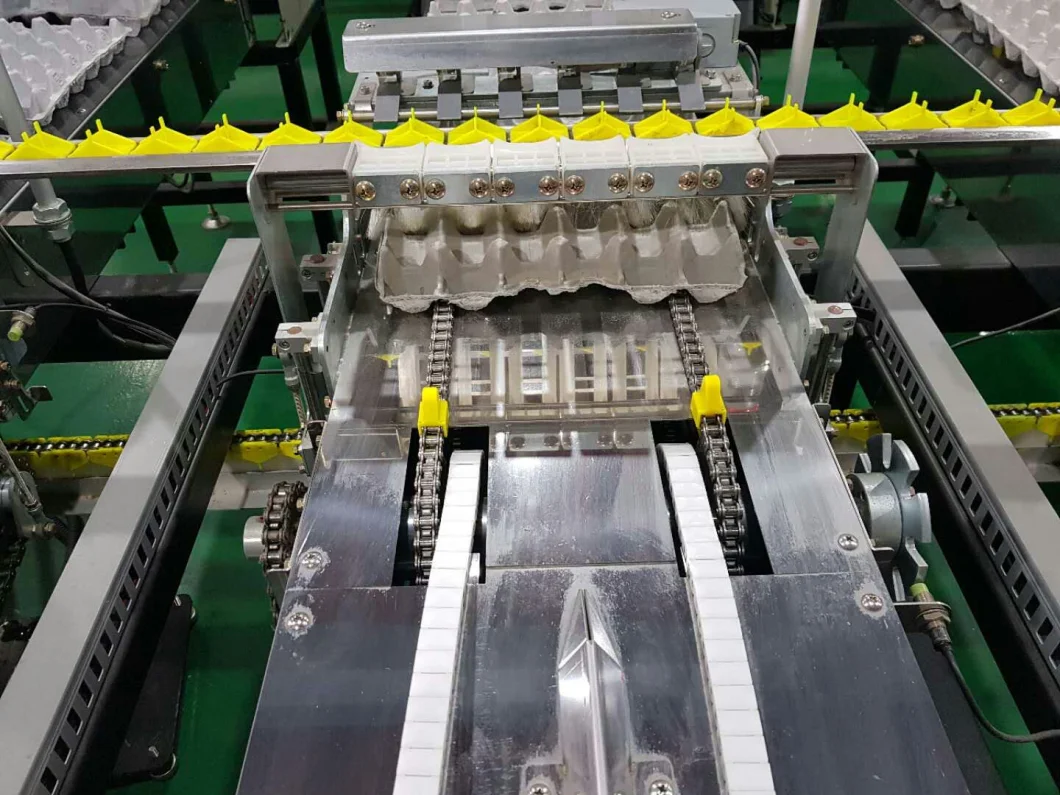

| 9 | Packing Unit (MOLD DISPENSER) 300W*1Ø | automatically supply egg tray and pack eggs into egg tray. With 10,12,15,18,30 etc. egg trays. 300W*1Ø Customized rating device specifications based on the specifications of the loading device |

Specification and Function Description for Each Unit

Contaminants in eggs are first excrement such as feces and urine of chickens, also dust and feat

hers in the house and various contaminants such as egg yolks, egg whites, and microorganisms t

hat are contaminated with broken eggs during the transfer process.These contaminants not only

make consumers dislike, but also pose a threat to food safety. Eggs are contaminated with micro

organisms and many impurities starting from laying eggs. The cleaning device is a process for

cleaning contaminants such as fecal urine, feathers, dust, egg white and egg yolk remaining on the

surface of the egg. Washing water temperature is at least 11°C higher than the temperature of the eggs,

continuous heating is used to keep the temperature of the washing water higher than the temperature of the eggs,

prevents wash water from penetrating inside the egg and contaminating the inside of the egg.

1,Deliver Unit

Transferred through the egg conveyor belt, eggs will be arranged neatly, and the unit for cleaning

efficiency is improved by once sorting broken eggs.

2,Cleaning Unit

Wash the egg with brush and wash the eggs three times before next process, to prevent bacteria

l contamination.

3,Drying Unit

When the air is forced by the fan, wipe the surface of the eggs with brush.

4,Ultraviolet Sterilization Unit

Removes and kills harmful bacteria such as E. coli, Staphylococcus, and molds. The results of te

sting the eggs sterilized by this unit showed that the sterilization effect was significant.

5,Checking Unit

Disposal of defective eggs (opaque, broken) in a dark room with light (three-wave length fluorescent lamps

and tungsten halogen lamps).

6,Packing Unit

Usually a set of equipment is divided into 5 levels according to weight, but according to the actual situation

of the farm, it can also be divided into 4 levels and 3 levels as a set of equipment.

Grading Device (30,000 eggs/hour)

The eggs are sorted according to the specified standards (extra large, extra large, large, medium, small, and other foreign products).

Packing Device

Automatic packing eggs transferred by cleaning unit and grading unit, improve the work e

fficiency. Contaminants in eggs are first excrement such as feces and urine of chickens, also dust

and feathers in the house and various contaminants such as egg yolks, egg whites, and

microorganisms that are contaminated with broken eggs during the transfer process.

These contaminants not only make consumers dislike, but also pose a threat to food safety.

Eggs are contaminated with microorganisms and many impurities starting from laying eggs.

The cleaning device is a process for cleaning contaminants such as fecal urine, feathers, dust,

egg white and egg yolk remaining on the surface of the egg. Washing water temperature is at

least 11°C higher than the temperature of the eggs, continuous heating is used to keep the temperature

of the washing water higher than the temperature of the eggs, prevents wash water from penetrating

inside the egg and contaminating the inside of the egg.