brewing equipment beer production line with boil kettle,mash tun/lauter tun,fermenter,filling machine and bottle washing machine

1.We are factory.

2.We supply good quality and competitive price.

3.We supply installation service.

4.We promise lifetime guarantee.

1. TurnKey brewery Project with high level technology.

2. Custom made for any size.

3. International standard stainless steel 304,316 and red copper material.

4. Seamless Welding&8 times Inner polishing.

5. Advanced produce equipment.

6. Leading manufacturer of craft brewing equipment in China.

| Daily Output | 100L | 200L | 300L | 500L | 600L | 800L | 1000L | 2000L | 3000L | 5000L |

| Unit Type | HL100 | HL200 | HL300 | HL500 | HL600 | HL800 | HL1000 | HL2000 | HL3000 | HL5000 |

| Floor Space | 15m² | 20m² | 25m² | 45m² | 55 m² | 70m² | 80m² | 120m² | 150m² | 250m² |

| Power | 8KW | 12KW | 20KW | 35KW | 35/15KW | 35/15KW | 35/15KW | 65/15KW | 65/15KW | 65/15KW |

| Electricity | 3P 380V(220V, 110V, 415V...) 50(60)HZ; 1P 220V(120V,110V,240V...) 50(60)HZ | |||||||||

Beer Brewing Equipment

Our product includes a variety of large, medium and small brewery equipment, hotel, bar home-brewed beer equipment, teaching experiment etc. And could be used to brew various types of wine, beer, barley-bree (whisky) brandy. We supply brewing of main and auxiliary raw material, technical training, secondary equipment and control equipment, of course, can customize according to customer required special specifications design, production, installation of equipment and other products.

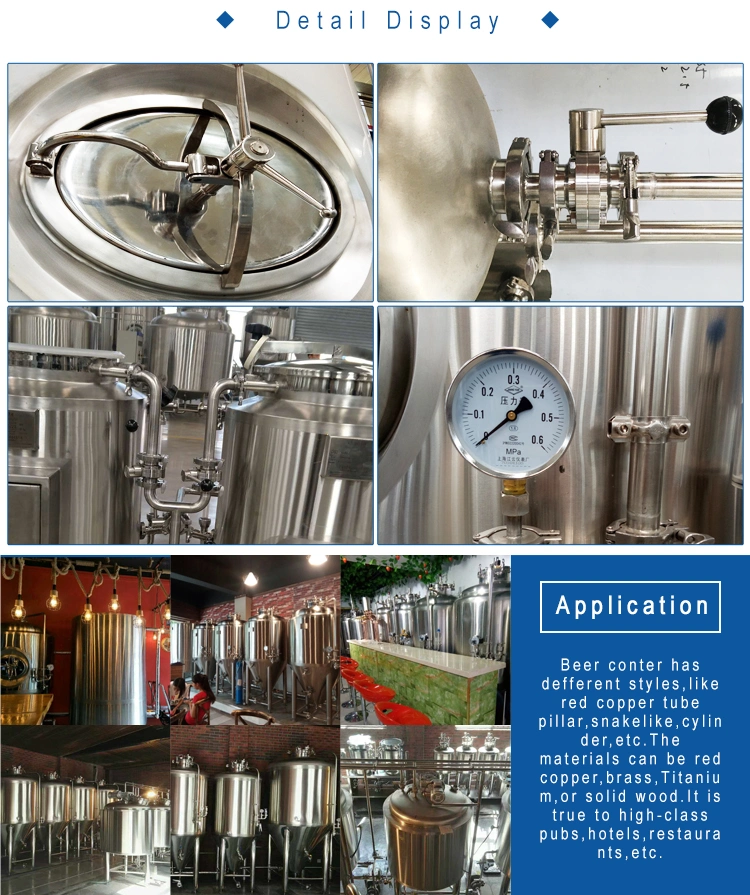

Brew house System

The brew house system could be included two-vessels brew house, three-vessels brew house and four-vessels brew house. Two-vessels brew house includes mash/lauter tun and kettle/whirlpool tank. Three-vessels includes mash tank, lauter tun and kettle/whirlpool tank. Four-vessels includes mash tank, lauter tun, boiling kettle and whirlpool tank. The capacity is bigger, the vessels is more. It is just in order to reduce the brewing time, improve the working efficiency.

Fermentation systems consists of Fermentation Tank and Bright Beer Tank.Fermentation Tank structure and design differs depending on fermentation process.the normal Fermentation Tank structure is dish head up and cone down,the tank is equipped with cooling installation,there is a cooling jacket on tank cone section,columnar part has two or three cooling jackets.This not only can meet the relevant requirements of cooling, guarantee cooling rate of fermentation tank, also help to precipitation and storage the yeast.

PRODUCT FEATURES:

- Desiging tanks and heating system according to craft, mash tank warming≥10ºC/minEnergy saving stir structure : large cross-section impeller, 15r/min speedSieve plate of filter tank includes welding sieve plate and milling sieve plate.Plow knife of filter tank separated to one foot, feet and bow plow knifeWort boiling heat way includes steam jacket, interior heating and exterior heating.Material includes stainless steel 304, 316 and red copper.

PRODUCT FEATURES:

- Our Fermentation tanks/tun available from 100L to 20000L and average 25% Head Space. All tanks have a Dish top, Cylinder body & 60/70° Cone Bottom. Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish. Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated. All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI. We can customize fabricate any tank to meet your brewery's space and height restrictions.

Our Company

Jinan Tonsen Equipment Co.,LTD.Jinan Tonsen Equipment Co., Ltd. is an international comprehensive enterprise specializing in R&D,production,technical support and services for beer equipment and wine equipment .Our company has 80 front-line production employees,10 production management staff,5 top Professional and Technical Personnel,the product includes large,medium and small brewery equipment,hotel/bars brewed beer equipment,teaching laboratory equipment,various types of wine equipment,and provide beer equipment accessories, auxiliary equipment,control equipment,supply the main and auxiliary materials of beer brewing,brewing technique training and other services.According to customers' different requirement,our engineers can design,produce and install special specifications of equipment and other products.Our company adhering to the principles of reputation foremost ,quality first,and focus on customers,to integrate wine culture and enterprise culture,we committed to creating a world leading brands "Tonsen" wine processing equipment.

brewing equipment beer production line with boil kettle,mash tun/lauter tun,fermenter,filling machine and bottle washing machine

We can customize the equipment according to your request!!!

Leave message to gain updated price and configuration.

I will reply to your in 24 hours!!!