Our factory professional produce different type gold washing trommel, diamond wash machine, rotary scrubber, vibrating screen and other type minine equipmen

---Product application---

| 1) Diamond mining 2) Alluvial gold, placer gold, gold sand 3) River dirt gold with clay, Clay alluvial 4) Desert sand, gold tailing... 5). Other type mining washing and classify and separation |

AS per different mining condition, we design the flowchart as below,

A). Washing trommel+Centrifugal concentrator+Shaking table;

B). Washing trommel+Jig machine(Jigger)+Shaking table;

C). Washing trommel+Sluice box with grass mat(carpet).

1). Trommel Screen

Working Principle:

| Material feed into the hopper by excavator,high pressure water released and wash the mineral,then,mineral by forward into the drum.It is lifted up by the rotation and aerated as it fall back down.This finer material passes through the screen openings while the large material tumbles towards its eventually exit at the real of the drum.After that,the final mineral and water go through the sluice bow which is consist with gold grass mat.The no use mineral are washed out and the gold are catched by the gold grass mat. China supplier mobile screen river gold washing machine trommel |

---Advantages---

| ♦Includes water pump, water pipe, diesel engine / electric motor, wheel, can be easy movable.Mobile with wheels, can free transport/move to other lace when finish the job. It is suit to small scale / large mine processing. ♦ Diesel engine / electric motor, can work in no power field. ♦ Bigger hopper,single / double layer screen designed. ♦ Water pump with water pipe release high pressure water. ♦ It is popular in African, Asian, South American due to its easy to move and easy to operate. ♦ It is low cost, miner just cost a little budget to buy one. Many miner came to our factory to buy it for their alluvial gold, river sand mineral, diamond mining. |

Technical Data of Trommel:

| Model | Capacity (t/h) | Wheel quantity | Water pump & water pipe | Diesel engine / Electric motor | Drum diameter | Drum length | Screen size | Weight (kgs) | |||

| GL510 | 5-15 | 4 | include | diesel engine / electric motor | 500 mm | 1300 mm | <3-20 | 1200 | |||

| GL615 | 10-20 | 4 | include | diesel engine / electric motor | 600mm | 1500 mm | <3-20 mm | 1500 | |||

| GL715 | 20-30 | 4 | include | diesel engine / electric motor | 600mm | 1500 mm | <3-20 mm | 1500 | |||

| GL815 | 30-40 | 4 | include | diesel engine / electric motor | 600mm | 1500 mm | <3-20 mm | 1500 | |||

| GL1020 | 40-100 | 4 | include | diesel engine / electric motor | 1000 mm | 2000 mm | <3-20 mm | 2300 | |||

| GL1225 | 100-160 | 4 | include | diesel engine | 1200 mm | 2500 mm | <3-20mm | 3000 | |||

| GL1530 | 150-200 | 4-6 | include | diesel engine / electric motor | 1500 mm | 3000 mm | <3-20 mm | 4000 | |||

| GL1545 | 200-300 | 4-6 | include | diesel engine / electric motor | 1500 mm | 4500 mm | <3-20 mm | 4500 | |||

GL1848 | 300-450 | 4-6 | include | diesel engine / electric motor | 1800 mm | 4800 mm | <3-20 mm | 6000 | |||

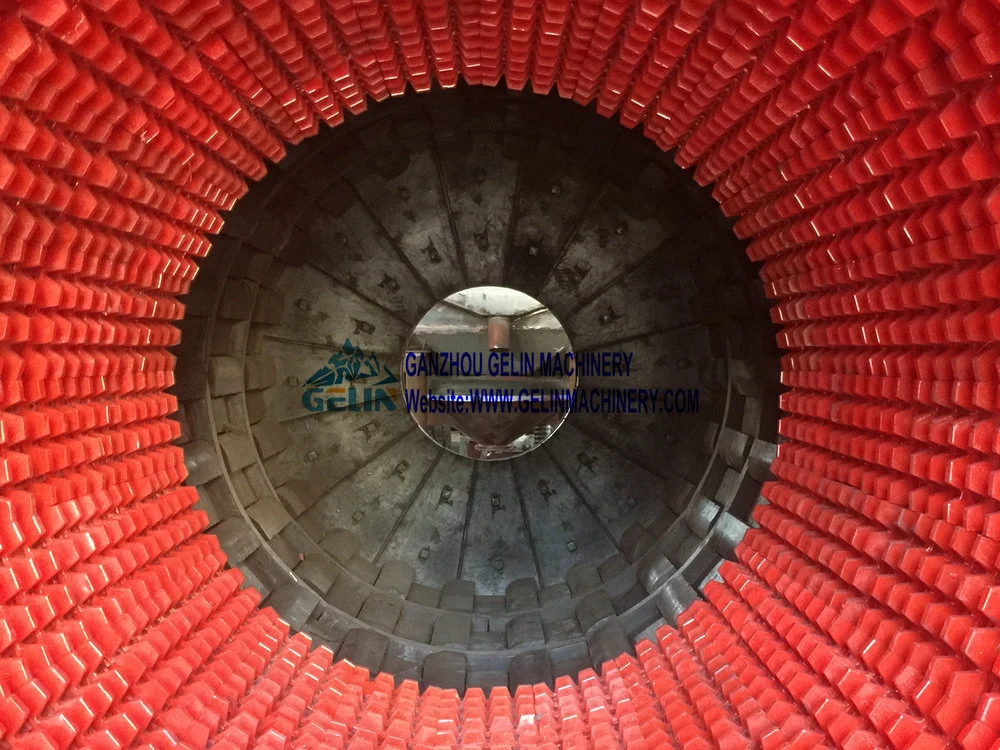

2). Rotary scrubber / Rotary scrubber Trommel

Suitable to wash clay and stickly alluvial mining, dirty stones.

Some clients are facing harsh mining environment of high density clays and mud, our G serious Rotary Drum Scrubber was born for washing out these enimies. Some times it coworked with auto washing belt to reach the best efficiency.

Gelin Drum Washing Machine, which is also named Drum Washing Machine, is the most advanced ore washing equipment at present in China. It is able to de-slime of the sand and stone, the drum inside is equipped with single or double layer round screen which can get 2 to 3 different size of sand stone products.

Rotary scrubber application: Tantalite mine, Gravel, clay gold mine, sticky mine, stone.

Mining clay gold processing machine rotary scrubber.

It is a mineral washing machine, designed to break up alluvial, gravels, clays and sand. It can accept material up to 230mm.

It is able to de-slime of the sand and stone, the drum inside is equipped with single or doublelayer round screen can get 2 to 3 different size of sand stone products, To which is applied pre-concentration of the materials contain mud, to promote the beneficiation index in the later steps and it is widely used to the washing of manganese, iron, limestone, tungstenore, silica and so on. The slurry material feeds into the drum where it is vigorously scrubbed, the soil matrix is broken up and the target mineral is released. The material is then screened through the rotating screen and waste is ejected. The screened material is then passed on to the concentrating modules for upgrading.

Features

Designed to break up alluvial gravels, clays and sand

High capacity and high power scrubbing

The long drum of the scrubber retains material for longer, more vigorous washing for complete separation

One high output electrical motor driving a gear system providing efficient torque

Adjustable rotary speed

The water with high pressure flushed the inwall of drum

Can accept material up to 230mm

Mechanical sealing of inlet chute minimal spillage when over feeding

Drive loads absorbed within the drive frame and pivoting drive frame design Foundations only have to support vertical load and are not critical for alignment ie minimal cost

Shell design less mass than conventional roller supported units installation craneage requirement reduced

Technical data of Rotary scrubber trommel:

| Model | Drum Size (mm) | Screen size (mm) | Rotation speed (r/min) | Feeding size (mm) | Water consumption (M3/h) | Angle of inclination (°) | Water pressure (Mpa) | Capacity (T/h) | Power (Kw) | Weight (T) |

| G1030 | Φ1000×3000 | 0.5-20 | 25-28 | ≤100 | 1.5-4 | 0.5-10 | 0.4-0.5 | 30-50 | 15 | 4.8 |

| G1136 | Φ1100×3600 | 0.5-30 | 25-28 | ≤100 | 1.5-4 | 0.5-10 | 0.4-0.5 | 40-60 | 15 | 5.2 |

| G1230 | Φ1200×3000 | 0.5-30 | 23-25 | ≤100 | 1.5-4 | 0.5-10 | 0.4-0.5 | 50-70 | 18.5 | 5.8 |

| G1430 | Φ1400×3000 | 0.5-30 | 20-23 | ≤150 | 1.5-4 | 0.5-10 | 0.4-0.5 | 60-80 | 22 | 6.2 |

| G1545 | Φ1500×4500 | 0.5-30 | 18-22 | ≤150 | 1.5-4 | 0.5-10 | 0.4-0.5 | 70-120 | 30 | 6.9 |

| G1560 | Φ1500×6000 | 0.5-30 | 18-22 | ≤150 | 1.5-4 | 0.5-10 | 0.4-0.5 | 80-130 | 37 | 8.3 |

| G1845 | Φ1800×4500 | 0.5-30 | 20-21 | ≤170 | 1.5-4 | 0.5-10 | 0.4-0.5 | 90-130 | 45 | 11.8 |

| G1860 | Φ1800×6000 | 0.5-30 | 20-21 | ≤170 | 1.5-4 | 0.5-10 | 0.4-0.5 | 100-140 | 45 | 12.8 |

| G2060 | Φ2000×6000 | 0.5-30 | 19-20 | ≤210 | 1.5-4 | 0.5-10 | 0.4-0.5 | 120-160 | 55 | 14.8 |

| G2265 | Φ2200×6500 | 0.5-30 | 19-20 | ≤230 | 1.5-4 | 0.5-10 | 0.4-0.5 | 160-180 | 55 | 16.5 |

Our company & Customers Visiting

Ganzhou Gelin Mining Machinery Co., Ltd is an expert manufacturer of mining machines in China. Our company is located in Guzhang Industrial Zone, Shicheng county, Jiangxi province, covering an area of over 30000 square meters, having more than 30 sets of heavy processing equipment and with an annual outpurt of more than 2000 sets of mining machinery.

--- PRE-SALE SERVICE ---

1.Based on clients' request and budget, GELIN experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to you for testing by courier, or, the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients' demands.

--- AFTER-SALE SERVICE ---

1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION ---

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

FAQ

Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and assistance.

A:1). What type is the mining? Is it rock stone? or it is sand?

2). If rock stone,What is the general particle size(mm) of the raw ore?

3). What is the handling capacity(tons per hour) you plan to work with?

4).What is the elements of the raw ore? How much percent % of each minerals?

Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the reasonable flowchart, suitable solution and equipments selection. etc.

Q: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of Gelin equipments is one year. And of course we will supply the spare parts for you for life-long time at lowest cost.

Q: If i need the complete mineral processing line. is Gelin able to help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you need.

There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality and service.

Welcome to visit our factory in your free time!