Stone production line,aggregate stone crushing plant is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electronic control.

Production Capacity:20-800t/h

Application Ranges:mining,stone crushing production

1 Various of coarse jaw crusher, fine jaw crusher, Hammer Crusher; Double-Roll Crusher; Cone Crusher; Impact Crusher; Rod-toothed Crusher; Hydraulic pressure cone crusher; Vertical combination crusher; High-efficiency fine impact crusher, sand making machine, vibrating feeder, belt conveyor, sand washing machine, hopper, with a feature of advanced structure, reliable operation, high quality and easy in use.

2 We can supply various complete plants to satisfy different quarry operation. It is also capable to provide the quarry design, facilities installation and regulation as a coordinated service process.

Our crushing equipment/stone crusher: Jaw Crusher, Hammer Crusher; Double-Roll Crusher; Cone Crusher; Impact Crusher; Rod-toothed Crusher; Hydraulic pressure cone crusher; Vertical combination crusher; High-efficiency fine impact crusher, sand making machine, vibrating feeder, belt conveyor, sand washing machine, hopper.

So whether you are looking for a stone crushing line or want to buy crusher equipments, call or email us, our specialized stuff and engineer will help you in time.

Working process of the aggregates stone crushing equipment :

aggregates stone crushing equipment flow is : Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder.

The crushed stone materials are conveyed to crushing plant by belt conveyor for secondary crushing before they are sent to vibrating screen to be separated.

After separating, qualified materials will be taken away as final products, while unqualified materials will be carried back to the stone crushing equipment for recrushing. And customers can classify final products according to different size ranges. All the final products are up to the related standards within and beyond China. Of course, according to different requirements, customers can adjust the size of their final products from this stone crushing plant. Process of Stone Crushing Plant

Clients will get the satisfactory products after objects being crushed for several times. Dust is generated during the working process while the dust control units are needed.

Main equipment list of the aggregates crushing equipment : (according to the actual requirement,can be changed)

1. 50-80 T/H aggregates stone crushing equipment

Item | Model | Motor(kw) |

Vibrating feeder | 960X3800 | 15 |

Jaw crusher | 500X750 | 55 |

impact crusher | 1010 | 55 |

Vibrating screen | 1235 | 11 |

high-efficiency fine impact crusher | 800X800 | 75 |

Sand washing machine | 2600 | 7.5 |

2. 100-150t/h aggregates stone crushing equipment

Item | Model | Motor (kw) |

vibrating feeder | 1100X4200 | 75 |

jaw crusher | 600X900 | 75 |

impact crusher | 1214 | 132 |

vibrating screen | 1545 | 15 |

high-efficiency fine impact crusher | 1000X1000 | 90 |

sand washing machine | 2800 | 11 |

3. 200t/h aggregates stone crushing equipment

item | model | power(kw) |

vibrating feeder | 1100X4900 | 16 |

jaw crusher | 750X1060 | 90 |

impact crusher | 1315 | 180 |

vibrating screen | 1854 | 18.5 |

high-efficiency fine impact crusher | 1300X1200 | 160 |

sand washing machine | 3200 | 15 |

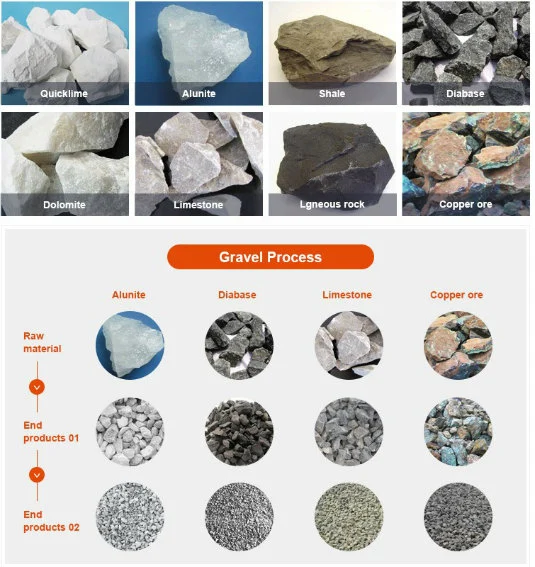

Final products of the aggregates:

About factory :

Contact : Sara 0086 137 8347 1727